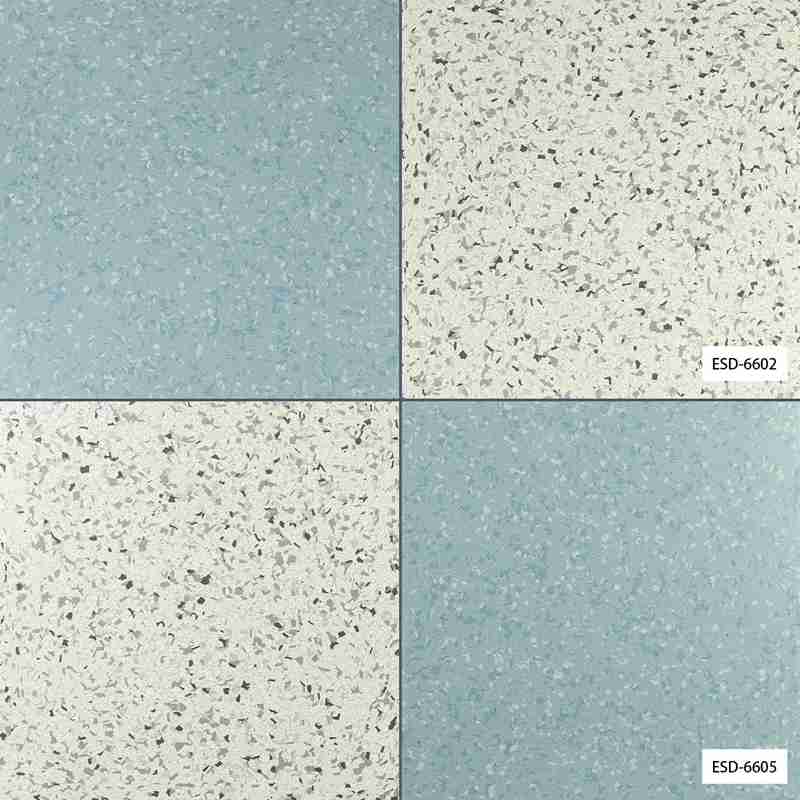

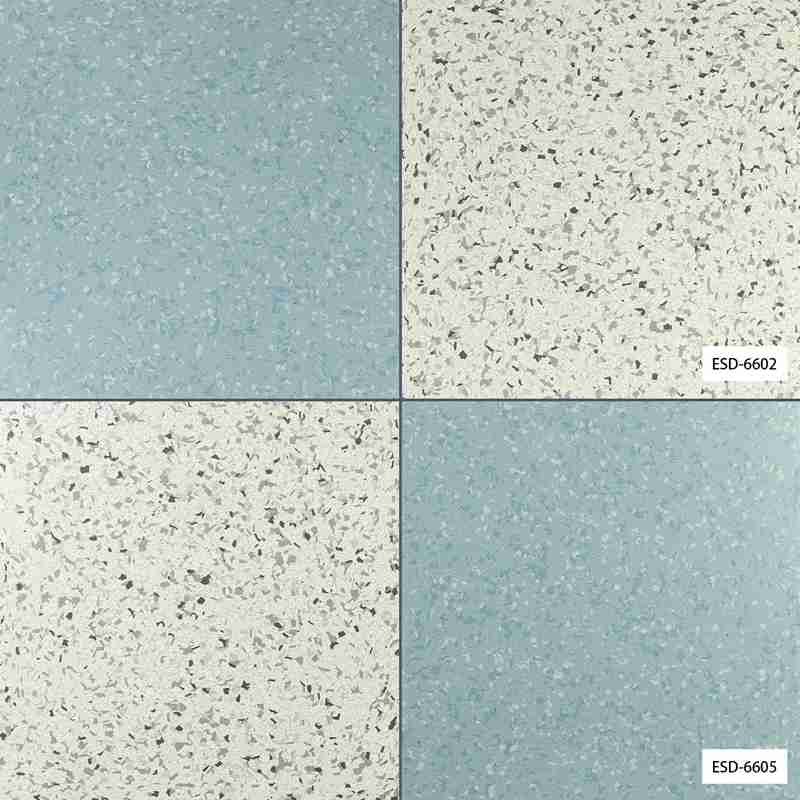

ESD Flooring 0027 is a specialy designed flooring solution that provides excellent electrostatic discharge (ESD) protection. This flooring system consists of three key components: anti-static flooring material, ESD conductive flooring, and static dissipative sheet vinyl.

The anti static flooring material used in Anti-static Flooring 0027 ensures effective dissipation of static charges, helping to prevent damage to sensitive electronic equipment. The material is resistant to abrasion, chemicals, and abrasion ensuring long-lasting performance.

Efficient Control Of Static: The static dissipative sheet vinyl will scrape up all the static electricity which is quite crucial because operations or electronics equipment can get disrupted when there’s a static buildup.

Sturdy with Longevity: Due to its high resistance to wear and tear, abrasion, and even staining, the flooring can sustain heavy machinery usage or a lot of foot traffic which is excellent.

Cost Friendly: While installing a static control system is quite expensive, static dissipative vinyl provides the opportunity to achieve the same functionality at a lower price without additional costs.

Easy Maintenance: The surface is smooth and non-porous meaning that the cleaning and maintenance would be a breeze which adds to the effort of maintaining a performant and clean working environment.

The static dissipative sheet vinyl is engineered in such a way that it can get rid of static electricity slowly. Unlike the traditional conductive flooring that allows static charges to be quickly grounded, this form of sheet vinyl finishes up the production of static electricity. This flooring is often used in cleanrooms and electronic assembly lines while providing the possibility to install the flooring in various commercial and industrial areas.

It is a cloth material which encloses an electric charge. Such a charge can be harmful to delicate electronic components or equipment as it prevents the formation of static electricity layer formation.

Starting with electronics manufacturing or computer servers rooms, and going through laboratories, cleanrooms, and even any rooms that require moderate static structure control.

Anti-slave films decrease the static layer formation by offering resistance which shrinks under the pressure of a static build up. Conductive flooring instead, assists in minimizing the resistance provided to electricity by offering it a direct flow to the ground. Anti-slave films are even tested to be effective for areas which require moderate static as additional placements are not required.

The process of applying it is rather effortless, with the sheets easily covering the desired sections and it can be installed in a similar manner to any other vinyl material. This can be possible on most Traditional subfloors after adjusting its condition.

The maintenance of the static dissipative vinyl is not difficult. Frequent cleaning of the vinyl with a damp mop and a very low concentration of caustic detergent is desirable. In addition, Remember to never attempt applying aggressive chemical cleaners or abrasive brushing as these will defeat the purpose of the vinyl and make the product ineffective.