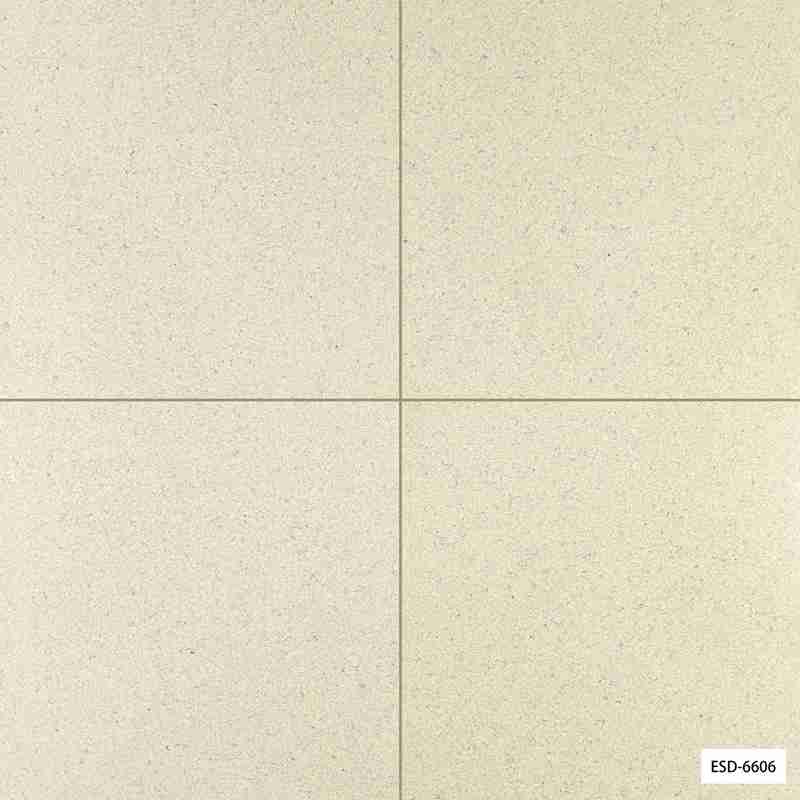

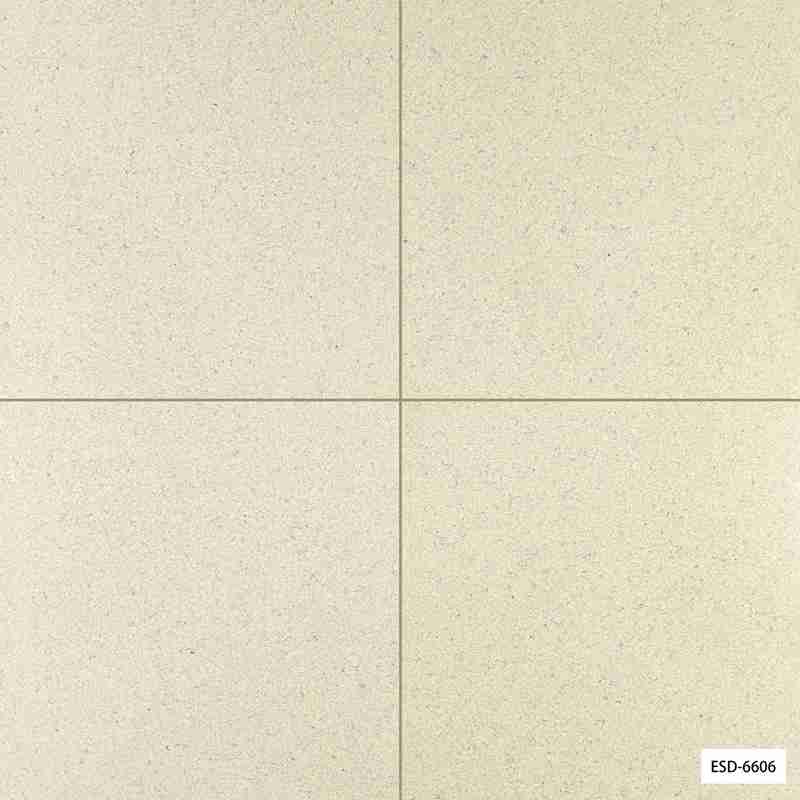

ESD 6606 is a state-of-the-art product that sets new standards for anti static conductive flooring. This cutting-edge flooring solution combines the benefits of anti-static and conductive vinyl flooring to deliver unrivaled static control performance.

The key feature of ESD 6606 is its unique combination of antistatic and conductive properties. This floor system is designed to effectively dissipate static electricity while maintaining a constant conductivity. Conductive vinyl controls static dissipation, prevents static charge buildup and minimizes ESD risk.

ESD 6606 offers exceptional durability and is ideal for high traffic areas. Conductive vinyl flooring is abrasion, impact and chemical resistant, ensuring long-lasting performance in even the most demanding environments. It is also easy to clean and maintain, providing a hygienic and aesthetically pleasing flooring solution.

Pre-eminent Static Control: The use of static conductive flooring materials is crucial in discharging static in the case of sensitive electronic equipment, medical devices or data centers where damage to critical systems has to be avoided.

Enhanced Durability: Flat and static conductive materials are able to withstand substantial foot traffic and industrial machine operations, making these materials long lasting even in stressful situations.

Safety and Reliability: The use of static conductive surfaces can be used to eliminate the charge which can result in ESD (Electrostatic Discharge) as a potential issue in environments containing sensitive devices and intricacies.

Easy Maintenance: The static conductive surface of the material is easily washable hence ensuring a safe environment without much cost.

A static conductive flooring elbow collar is made with the objective of allowing a safe means of static discharge to the ground. As a result of its special construction, the collar is fitted with conductive inserts which interlink with properly grounded static systems and inhibit static from forming. This type of flooring offers electrostatic discharge storm protection, increased operational security, and comes in many different looks to add ESD protection to high-tech, industrial, or commercial operations.

A static conductive floor is a type of flooring made in such a way that it directs the electrostatic discharge (ESD) to a safe place, that is to the ground so that static electricity cannot accumulate and there is no danger to sensitive devices or other equipment.

It is ideal for environments such as electronics manufacturing, server rooms, cleanrooms, medical facilities and any other place where static electricity can create a problem and equipment and processes can be compromised.

The conductive floors designed in this manner are coupled with a ground system so that any static electricity created automatically flows to the ground. This reduces the potential and risk of static build up which can lead to a dangerous ESD occurrence.

No, designing the static conductive floor is not a difficult task, in fact it is easy. It can be provided in different designs such as tiles or rolls and even has provision for a grounding system.

Maintenance of anti static flooring is smooth and straightforward. Regular cleaning with a wet mop and non- abrasive detergent is generally sufficient to keep the surface dust and debris free, ensuring it functions effectively.