ESD Vinyl Sheet, or electrostatic discharge Vinyl Sheet, is a specialized flooring material designed to control and dissipate static electricity in environments where electrostatic discharge (ESD) poses a risk. This sheeting is particularly crucial in industries such as electronics manufacturing, laboratories, and cleanroom facilities where static-sensitive equipment and devices are prevalent.

The ESD Vinyl Sheet is engineered with conductive properties that allow it to rapidly and safely discharge any accumulated static electricity, preventing damage to sensitive electronic components. It serves as an effective grounding solution, ensuring that personnel and equipment are protected from electrostatic charges.

This flooring material is known for its durability and resilience, providing a long-lasting solution for environments with heavy foot traffic or the movement of ESD-sensitive equipment. The smooth and seamless surface facilitates easy maintenance and cleaning, meeting the stringent cleanliness requirements of industries such as pharmaceuticals and semiconductor manufacturing.

Static Dissipation:

The primary function of ESD Sheet Vinyl Flooring is to control and dissipate static electricity, preventing the build-up of electrostatic charges that could potentially damage sensitive electronic components.

Conductive Properties:

Engineered with conductive materials, this sheeting provides a reliable and controlled path for the discharge of static electricity, ensuring a safe environment for electronic devices and equipment.

Durability:

ESD Vinyl Sheet is designed for durability, making it suitable for areas with heavy foot traffic or the movement of equipment. Its robust construction ensures a long lifespan, reducing the need for frequent replacements.

Seamless Surface:

The smooth and seamless surface of the ESD Vinyl Flooring minimizes areas where dust and contaminants can accumulate. This is particularly beneficial in cleanroom environments and industries with stringent cleanliness requirements.

Easy Maintenance:

The smooth surface also facilitates easy maintenance and cleaning. Regular cleaning routines can be efficiently implemented, contributing to a hygienic and well-maintained environment.

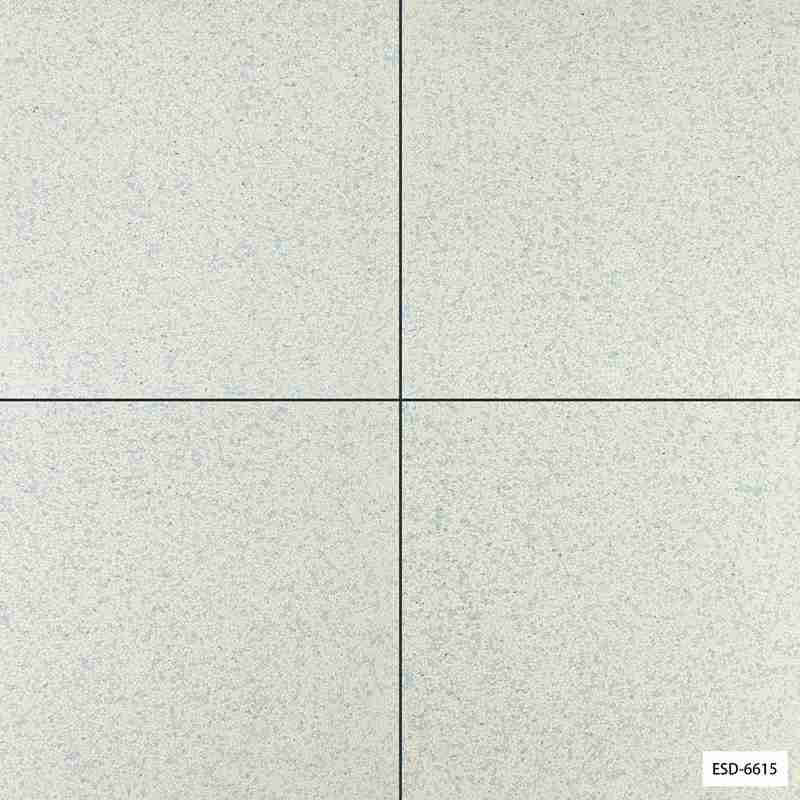

Customizable Design:

ESD Vinyl Tile is available in various colors and designs, allowing for customization to meet aesthetic preferences while maintaining its essential static control functionality.

Compatibility with Grounding Systems:

The sheeting is compatible with specialized grounding systems, establishing a reliable pathway for static dissipation. This ensures that personnel, equipment, and sensitive components remain protected.

Versatility:

Suitable for a range of industries, including electronics manufacturing, laboratories, and cleanroom facilities, Anti Static Flooring offers versatility in its application, providing static control in diverse environments.

Electronics Manufacturing:

ESD Vinyl Sheet is extensively used in electronics manufacturing facilities where static control is paramount to protect sensitive electronic components and devices from damage caused by electrostatic discharge.

Cleanroom Environments:

In cleanroom settings, especially those within industries like pharmaceuticals, biotechnology, and semiconductor manufacturing, ESD Vinyl Sheet helps maintain a controlled environment by preventing static charges that could attract and hold particulate matter.

Laboratories:

Research and testing laboratories, particularly those dealing with delicate instruments and electronic equipment, benefit from the static dissipative properties of ESD Vinyl Sheet to safeguard against electrostatic discharge.

ESD Vinyl Sheet, or Electrostatic Discharge Vinyl Sheet, is used to control and dissipate static electricity in environments where electrostatic discharge (ESD) poses a risk. It is commonly employed in industries such as electronics manufacturing, cleanrooms, laboratories, and technology workspaces.

ESD Vinyl Sheet works by providing a conductive path for the dissipation of static electricity. It is designed to prevent the accumulation of electrostatic charges, protecting sensitive electronic equipment and components from damage.

ESD Vinyl Sheet is installed in environments where static control is crucial. This includes electronics manufacturing facilities, cleanrooms, laboratories, server rooms, data centers, and areas with sensitive medical or precision equipment.

Yes, ESD Vinyl Sheet is suitable for server rooms and data centers to control static electricity and protect sensitive electronic equipment, ensuring the reliable operation of servers and networking devices.

Absolutely. ESD Vinyl Sheet is commonly used in cleanroom settings to prevent static charges that could attract and hold particulate matter, maintaining a controlled and contamination-free environment.

ESD Vinyl Sheet is typically installed using adhesive methods. Proper installation is crucial to ensure the conductivity and effectiveness of the sheet in controlling static electricity.

Yes, ESD Vinyl Sheet is available in various colors and designs, allowing for customization to meet both functional and aesthetic requirements.

Yes, ESD Vinyl Sheet is designed for easy maintenance. The smooth and seamless surface facilitates cleaning, contributing to a hygienic environment, particularly in cleanroom or laboratory settings.

High-quality ESD Vinyl Sheet is often manufactured to comply with industry standards and regulations related to electrostatic discharge control, ensuring it meets the necessary performance criteria.

No, ESD Vinyl Sheet is specifically designed for indoor use. Outdoor exposure may compromise its effectiveness in controlling static electricity.

Your home, it’s where you work, sleep, learn, meditate, cook, garden, work out and cool down. It expresses who you are. Now more than ever. So why not design it that way? We couldn’t agree more. we are firm believers of self expression. It’s why we design floors in the first place. Because a space that truly feels like you, begins with a floor that feels like you.