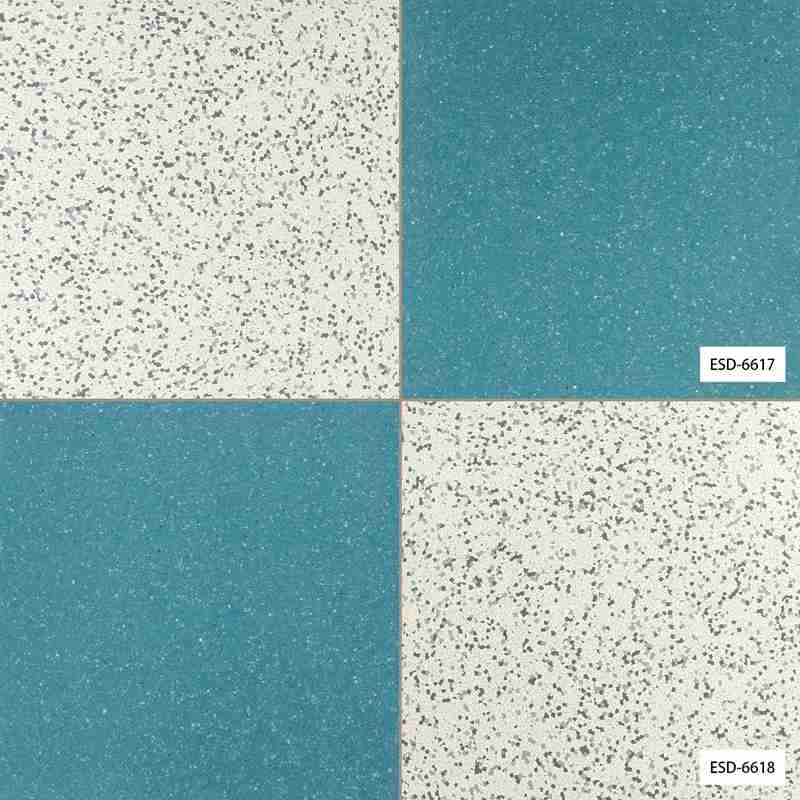

In China, all steps of the entire industry process regarding our ESD Epoxy Flooring construction are completed in our company, including manufacturing in the Jiangsu Province city of Nantong ESD-6617 where there is a strong conductive layer suited for clean rooms, electronic industry plants and labs. Combining style and advanced static-dissipative properties, this flooring option will contribute to the streamlined appearance of the interior and enhance its functional use. Since we are reliable as an ESD Epoxy Flooring factory in China, we strive to do so in each product because it must comply with the relevant quality of all items.

Smooth Homogeneous and Clean Floors: Since the epoxy flooring is seamless and has no edges, dust and bacteria will not accumulate at the junction line therefore, it is safe for use in clean rooms, hospitals and even the pharmaceutical facilities.

Enhancement of the operational activities: ESD epoxy flooring increase the efficiency of many processes as it reduces the chances of equipment damage as, for instance, malfunctions and data loss that might affect the operations of the critical surroundings.

Flexibility of design: The patterns and colors available in the ESD epoxy flooring can freely be incorporated in any facility and organized according to the workflow where different colors indicate sections of the facility.

Capability to withstand chemicals/spills: Because epoxy is a lot more resistant to chemicals solvents and even spills, it is fit for use in industrial settings where such substances are in plenty.

Economical: The upfront cost of installing is higher, but the low cost of maintenance and the long lifespan of the ESD epoxy flooring makes this a cost effective measure.

Automotive and Aerospace Manufacturing: The manufacture of ESD epoxy flooring is for use in manufacturing plants and facilities whereby static sensitive components like sensors, wiring and electronic systems are integrated in vehicles and airplanes.

Pharmaceutical Manufacturing: In drug production processes, dust and particles must be minimized to protect product purity. ESD epoxy works as a protective floor to ensure safe production by providing a clear and static-free environment.

Telecommunication Hubs: Communication facilities operate under ESD flooring to ensure that electrostatic discharge from communications equipment does interrupt the facilities and does not impede their life span.

Warehouses for Electronics Components: ESD epoxy can also be suited for warehouses storing electronic parts and components to reduce the risk of static charge and damage on the products handled.

Printing and Packaging Facilities: ESD epoxy flooring reduces the build up of static charges that can interfere with the various processes involved in printing and packaging processes to reduce problems such paper jams and misprinting.

ESD (Electrostatic Discharge) epoxy flooring refers to a flooring that aims to avoid and control the charging of static electricity by distributing static charge across a surface. It is mostly done in industries that are very sensitive like electronics manufacturing, data centres, or laboratories.

It is the best ESD epoxy flooring solution for sensitive equipment protection, safety enhancement, reduction of downtime, provision of high durability, easy maintenance surface, enhanced resistance of traffic and chemicals.

As long as they are well taken care of, ESD epoxy flooring can last longer than 10 years as long as the environment and usage live up to expectations.

Your home, it’s where you work, sleep, learn, meditate, cook, garden, work out and cool down. It expresses who you are. Now more than ever. So why not design it that way? We couldn’t agree more. we are firm believers of self expression. It’s why we design floors in the first place. Because a space that truly feels like you, begins with a floor that feels like you.